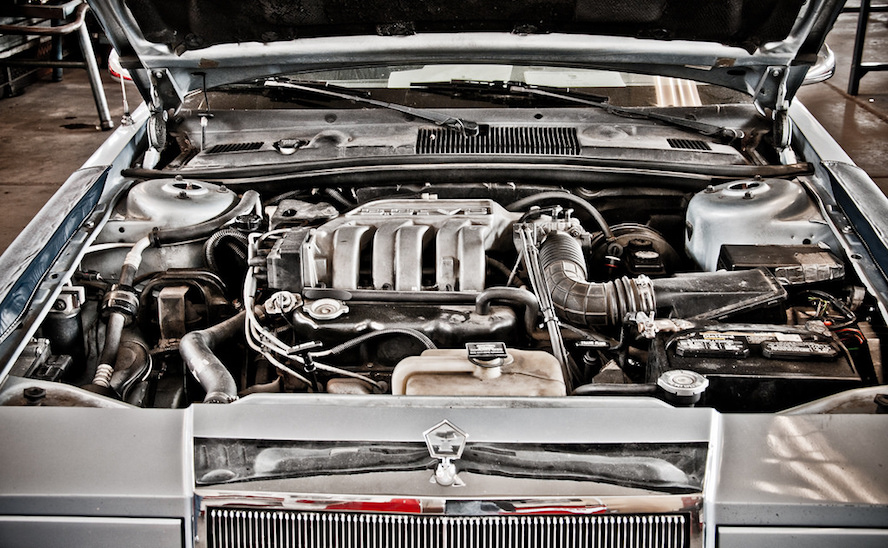

If you ran your vehicle without an air filter, you'd get the most efficient, zero-restriction air flow possible and would likely see amazing performance and fuel economy. You'd also end up with a damaged, clogged-up fuel-delivery system within a couple of days, as dust, pollen, spores, and other particulates get inhaled by the engine.

Remember that your engine needs air, fuel, and spark to run, and anything you can do to enhance the volume of air that enters the engine (while providing filtration) will help power and fuel economy. That's why ram air systems and hood scoops were developed all the way back in the '40s and '50s, serving as a "resonance supercharger" that directed more cold air into the carburetor and fuel system.

But what's the right compromise between air flow and filtration?

Oil Bath Air Filters

One of the earliest systems for air filtration on internal combustion engines was the oil bath filter. In an oil bath filter, air enters the filter and is directed over a sump of motor oil, which is designed to catch and filter out larger particles. The air then takes a turn and goes through a filter element, filtering out smaller bits. The filter element was typically a foam or steel mesh (early cars used a mat of horsehair!), which would have to be cleaned with kerosene at regular intervals, along with a change of the oil in the sump.

Oil-bath air filters were all well and good for the time and are actually still used on some industrial engines that have to operate in dirty, dusty environments. They were also inefficient, though, and inherently messy to service. By the late '50s, the oil-bath air filter had been mostly replaced with...

Pleated Paper Air Filters

You've seen the pleated paper air filter before. On a carbureted engine, they'd be ring-shaped and would sit inside a big housing on top of the carburetor, usually with a snorkel that would concentrate air flow into the fuel system. Paper air filters use a medium of compressed fibers, folded into pleats to increase surface area. Air makes its way through microscopic passages between chunks of fiber, and particulates are trapped before they can make it through these tiny holes. That means that these holes eventually become obstructed and, as the filter collects more dirt and dust, air has to find alternate routes in the filter medium. After about 10,000 miles, the filter needs to be changed.

To meet minimum filtration standards, though, the filter medium has to be dense and/or thick, and, by design the paper filter is going to be restrictive to air flow even when it's new out of the box.

Foam Air Filters

You still see foam air filters on lawn mower engines and other applications, and for a while they were touted as a great innovation for automotive use. Foam filters come with their own problems. They seem like a great idea—they're just a simple open-cell layer of foam that's saturated with a light oil that makes it tacky enough to filter and retain particulates. Theoretically, foam filters are cleanable and reusable, but in practice they're actually pretty difficult to clean thoroughly. Less-restrictive foam filters don't do a good job of filtration, and the ones that do meet filtration standards tend to strangle engine performance. In addition, the lack of pleats with a foam air filter means less surface area to trap particles as they come through the medium. For these reasons, foam filters have fallen out of favor.

Cloth Air Filters

What a simple concept—an air filter that's just layers of cotton gauze material, saturated with a light oil. These filters, pioneered by K&N in the late '60s, sandwich the layers of cotton gauze between a wire mesh frame that's formed into pleats. As a result, the filter layers use a "depth loading" principle in which the dirt that's trapped actually becomes part of the filter medium, as opposed to the "surface loading" of a paper filter.

Unless you're driving on gravel and dirt roads a lot, a cloth air filter can go for 40k miles or more before it becomes saturated enough with dirt to significantly affect air flow. When the service interval does finally come around, the filter is cleanable and reusable and will last the entire life cycle of your vehicle (with the right maintenance). Cleaning is a simple process, with an application of a specially-formulated solvent to loosen dirt and debris, a rinse with cold water and then a treatment with specially-formulated oil.

It can be hard to back up claims of improvements in fuel economy or power, but K&N does certify that every air filter it manufactures has enhanced filtration and air flow, according to ISO industry-standard testing. In the end, it does make pretty good sense to use a reusable air filter that provides better performance and doesn't have to be replaced every 10-15k miles.