Pop the hood on just about any newer vehicle, and you'll see a lot of wires and connectors without a whole lot of room to work on anything. It's pretty intimidating if you don't know what's what and how things work! We're here to clear that up.

Source | Joe Ross

Engines of yesteryear

Forty years ago, engines still used carburetors, distributors, plug wires, and vacuum-actuated spark advance to adjust timing according to load and demand. That's all a thing of the past now, of course. For a period in the '80s, when engine control modules weren't mature yet, there were “feedback carburetors" that used input from various sensors to adjust fuel metering, emissions, idle speed, and other drivability factors. These patched-together early systems worked reasonably well but couldn't adapt easily as the miles accumulated and engines started to wear and get “looser." It was one of many transitional technologies that were baked in the cake with '80s vehicles, making the decade a pretty low point for the industry.

Today's standard ECU

Starting in 1996, the industry went over to the OBD-II standard for all vehicles sold in the United States. OBD-II made it much easier for techs to troubleshoot problems by connecting a code reader to the vehicle's diagnostic port. The code reader or scanner gives the tech access to any trouble codes that have been stored in the engine's computer, which would illuminate the "check engine" light on the dash.

The engine relies on input from sensors throughout the engine and drivetrain, and uses this information to control timing, fuel metering, spark advance, transmission shift points, emissions, and other drivability factors.

Here's a quick breakdown of some of the main sensors and their functions:

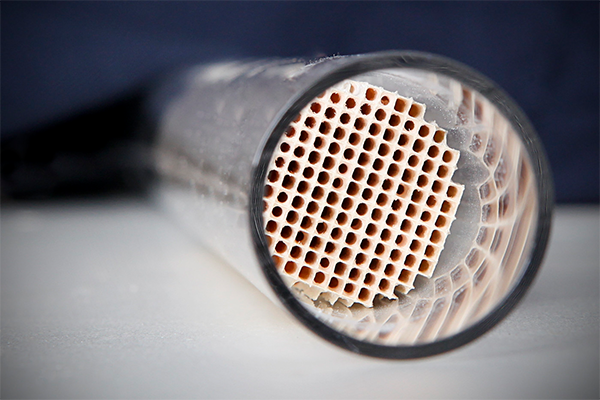

- O2 sensor: The O2 sensor(s) in the exhaust stream monitor the makeup of the exhaust gases and send this information back to the computer to govern fuel/air ratio and emissions. It's typically mounted on the exhaust pipe, not far behind the exhaust manifold; some vehicles have an O2 sensor near the catalytic converter as well.

- Coolant temperature sensor: This sensor does more than just alert the driver to an overheating condition. The information from the coolant temp sensor is used by the powertrain control module (PCM) to supply a richer fuel mixture until the engine is warmed up. When the engine is close to operating temperature, the signal from the O2 sensor will show a rich mixture, and the PCM will change fuel metering to normal.

- Throttle position sensor: The PCM uses information from this sensor to change spark timing and fuel mixture according to engine load or acceleration.

- Airflow sensor: There are usually several types of airflow sensor; its job is to monitor the amount of air that is entering the engine and affect fuel metering strategy. Manifold absolute pressure and manifold air temperature sensors are also part of this circuit.

- Crank position sensor: The crank position sensor monitors engine RPMs, information that is used to control spark timing, fuel delivery, and idle speed. Camshaft position sensors also serve this purpose, especially on vehicles with variable valve timing.

- Manifold absolute pressure sensor: The MAP sensor measures engine vacuum at the intake manifold, information that helps indicate engine load. The MAP sensor helps govern ignition timing and fuel delivery.

- Knock sensor: Spark knock occurs when timing is too advanced; knock sensors give the PCM a signal that will retard timing to prevent knock.

- EGR position sensor: This one is a crucial part of emissions controls, telling the PCM when and how much the exhaust gas recirculation valve opens.

- Vehicle speed sensor: Like the name says, this sensor just indicates how fast the vehicle is traveling, which the PCM uses to govern transmission functions, ABS braking, vehicle stability control and other systems.

While these features are all pretty advanced, one thing's for sure. Eliminating carburetors, distributors, ignition points, and all the old systems of a generation ago has resulted in engine management systems that are more powerful and fuel-efficient, and no longer need a tuneup every 35,000 miles.