You probably know that the Check Engine Light (CEL) on your dashboard can be illuminated for all kinds of reasons. Since the standardized OBD-II system was adopted in the mid-90s, those "reasons" are stored in your powertrain control module (PCM) as trouble codes that indicate a reading from a sensor or system that's out of spec.

That said, you probably also know that the OBD-II system takes a lot of the guesswork out of troubleshooting and repair. When a technician connects a code reader to your car's diagnostic port (usually under the dashboard), he can quickly access the codes stored in the PCM and at least get a rough idea of where to start on repairs.

Note: Code scanning is one of the free services at your local Advance Auto Parts store.

The tricky part, however, is interpreting what the trouble codes mean. Sometimes multiple trouble codes might be stored, all pointing to the same problem, and it can take a certain ability to "read the tea leaves" and pin down what the exact issue is.

What It Means

Since the late 80s, the oxygen sensor has been a vital part of emission controls on vehicles. This sensor monitors the content of exhaust gases as they make their way through the manifold and exhaust system, sending feedback to the PCM which is used in fuel metering and delivery. The O2 sensor needs to be at a certain operating temperature to deliver an accurate reading. Rather than wait until the engine warms up, the sensor contains a heating element to reach operating temperature more quickly, for better fuel economy and emission control.

A P0038 code means that the voltage reading from the O2 sensor on cylinder bank 1 is too high and is out of normal operating range, registering a code. In most cases it's the heater itself that's failed, which still means replacing the sensor; these sensors usually have a life cycle of about 75,000 miles. In some isolated cases the problem could be a driver for the heater itself, a shorted control circuit, a corroded or loose wire or blown fuse, so it's smart to rule these possible causes out before jumping the gun.

If you're wondering what "Bank 1" and "Sensor 2" actually means on your vehicle, you're not alone. Let's break it down.

Identifying Bank 1

Four-cylinder engines are simplest, so we'll start there. An inline four-cylinder engine only has one bank, and therefore usually only one catalytic converter. The trouble code will still specify "Bank 1" because the codes are standardized, but you can ignore that because there is no Bank 2.

Many vehicles have V6 and V8 engines, though. On these engines, each arm of the "V" is a bank. Each of those banks may have its own catalytic converter, which is why the P0037 code specifies Bank 1, Sensor 2. Consulting a repair manual for your vehicle is the best way to correctly identify each bank because this varies by manufacturer and vehicle.

Identifying Sensor 2

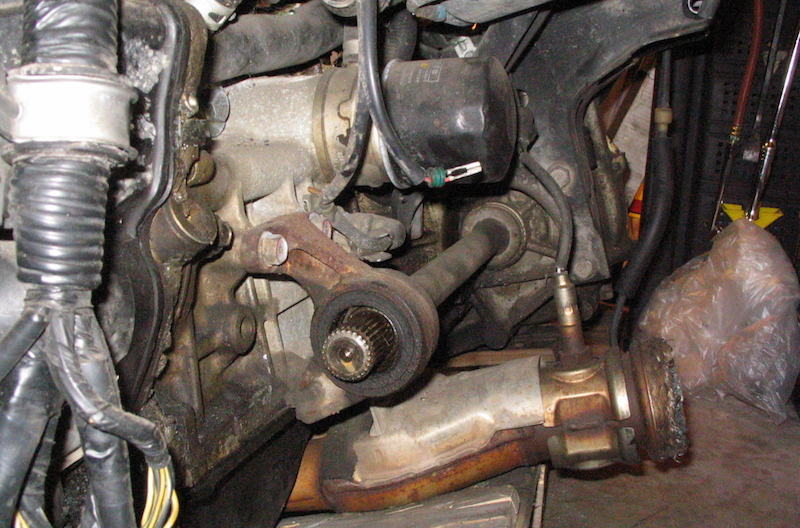

Once you have narrowed in on the correct bank, distinguishing between sensor 1 and sensor 2 is more straightforward. Sensor 1 is generally located close to the exhaust manifold, and it's placed before the catalytic converter. Sensor 2, on the other hand, is located after the cat. You should be able to identify sensor 2 by visually tracing the exhaust stream on your vehicle.

O2 Sensor Operation

The O2 sensor has a platinum-coated bulb that protrudes into the exhaust stream, with two platinum strips inside the bulb serving as electrodes. The electrodes are then vented to ambient air outside, and the difference in O2 levels between the hot exhaust and outside air will generate an electrical signal.

When the system is running rich, the O2 sensor will send a signal of about 0.9 volts, and when it's too lean the signal will drop down to about 0.1 volts. The ideal fuel/air mixture is about 14.7 to 1, which will generate a reading of around 0.45 volts.

Symptoms

- Illuminated CEL

- Poor fuel economy

- Poor engine performance

- Heightened emissions

- Possible rich-running condition and black exhaust smoke

What Happens If I Ignore It?

Ignoring an O2 sensor code won't keep your vehicle from running, but it'll hurt your fuel economy and performance. Your vehicle also will not pass an emissions inspection.

Diagnosis and Repair

- Check to see if there are any other trouble codes along with P0038 and, using a scanner, clear all the codes.

- Visually inspect the wiring around the O2 sensor for damage, corrosion or loose connections. If the wiring on the sensor itself or the terminal is damaged, replace the sensor.

- Check the ground for the sensor with a multimeter. If ground is intermittent or nonexistent, clean the ground and ground wire then repair.

- Check voltage to the O2 sensor. No current to the sensor would suggest a blown fuse or break in the wiring.

- If all measurements are within spec, then it's time to replace the oxygen sensor.

NOTE: After tens of thousands of heat/cool cycles, the threads for the O2 sensor can become pretty seized-up. It's advisable to use a strong penetrant like PB B'laster and let it sit for a good while (with the O2 sensor and exhaust pipe still warm) before trying to remove the sensor. This part can sometimes be difficult to get to; a specially-designed O2 sensor socket can make the job go a little easier. For more detailed instructions, read on.

Is this a code you've come across before? What did you do to fix it? Let us know in the comments.