Unless you've owned a car with a broken air conditioning system, it's hard to imagine having to slog through the long, hot summer in a vehicle that's just as hot inside as everything else is outside. We treasure our cool climate, whether in the home, the office, or somewhere in between at the wheel of our cars. But air conditioning is a relatively modern invention—about half as old as the car itself. So who were the early contributors to our freedom from summer's brutal reign? Read on to find out.

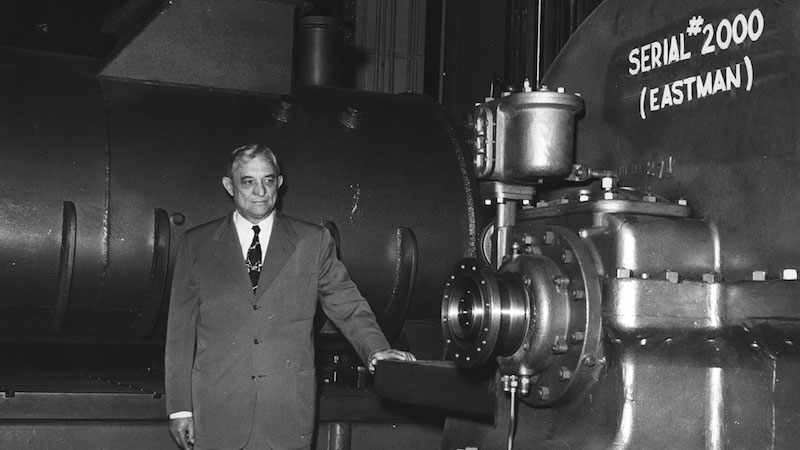

Willis Carrier | Carrier

Willis Carrier

The most important figure in any discussion of air conditioning in the modern sense is undoubtedly Willis Carrier. Yes, that Carrier—there's a good chance your home's A/C unit bears his name.

In 1902, Carrier invented the first modern electrical air conditioning unit. Just like today, the unit's duties were:

- Controlling temperature

- Controlling humidity

- Directing air circulation and ventilation

- Purifying air in circulation

Carrier's impetus for figuring out the electric-powered air conditioner was to improve the quality and uniformity of specialized printing runs for a printing plant. As a result, the systems that created the cool air were large, bulky, and had little potential for any other use.

It would take a little more than a decade for the wealthiest Americans to begin installing the first air conditioning units in their private homes. But it would be several decades before others managed to engineer a solution that was compact and light enough to fit in a car, while also being effective enough to be worth the hassle.

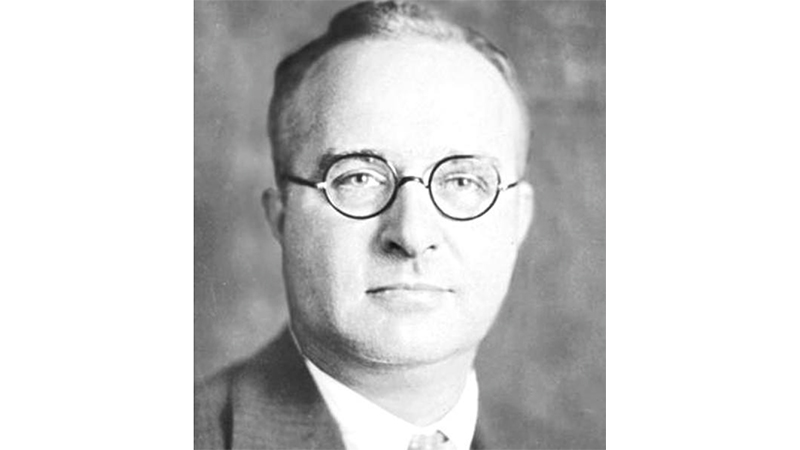

Thomas Midgley Jr. | Creative Commons

Thomas Midgley Jr.

Carrier's air conditioning design used cold water in the cooling portion of the device, but that only allowed a small potential for cooling the ambient air. To get much colder air temperatures, and do it quicker, pressurized refrigerants were necessary. That's where controversial inventor Thomas Midgley Jr. came in.

Midgley started out as an engineer for General Motors, working in their Dayton Research division (later Delco), and discovered that tetraethyl lead as a gasoline additive would stop spark knock in engines. While pressurized refrigerant air conditioners had been created and used before, it was Midgley who found a way to use a nontoxic, nonflammable refrigerant to keep things cool. Previous systems had used dangerous chemicals like propane, chloromethane, sulfur dioxide or ammonia, but what was needed was something chemically inert and safe. Midgley's system combined fluorine and hydrocarbons to create Freon, or R12 as it's also known.

R12 powered the first automobile air conditioning systems, and that same refrigerant would continue in use in the U.S. until 1994, when R12 was banned and replaced with R134a, due to R12's environmental hazards.

Edward L. Mayo

Even though the air conditioning scene for buildings and other enterprises was going gangbusters, it wasn't until 1938 that a serious attempt to provide air conditioning for cars was patented. That year, Edward L. Mayo, working for the Bishop & Babcock Mfg. Company of Cleveland, Ohio, applied to patent the Bishop & Babcock Weather Conditioner. The system included not only an air conditioner but a heater, too.

Mayo's design was innovative and, for the time, very compact. Still, it took up considerable space in the vehicle's interior, typically occupying a significant portion of the available trunk space. It was also expensive and didn't have any temperature controls other than an on-off switch. As a result, the system never gained much widespread use and was eventually discontinued.

Later systems, after WWII, blasted cold air from the rear package shelf, freezing out rear seat passengers and creating a great deal of drippy condensation while the front seat passengers sweated. In addition, controls were on the package shelf, necessitating a jump into the back seat to turn the unit on or off. Some early designs ran continuously, meaning it was necessary to pop the hood and remove an engine belt to even shut the unit down. Finally, the option was over $400 — which comes to nearly $5000 in today's dollars.

Nils Erik Wahlberg & Joseph F. Sladky

Another decade and a half passed before the next big advance in air conditioning arrived, by way of the Nash-Kelvinator company and its engineers, Nils Erik Wahlberg and Joseph F. Sladky. Filed in 1950, and approved in 1954, the patent showed an automobile air conditioning system that put all of the components required to manage the cabin air temperature under the hood and cowling. They were tucked away from the passenger and cargo space, meaning the system required no real compromise.

It was called the All-Weather Eye—less expensive and easier to assemble and install than previous systems. And unlike its predecessors, the All-Weather Eye didn’t drive the air conditioning compressor continuously, whether it was being used or not. Instead, it used an electrically operated clutch to engage or disengage the compressor as needed—just like on modern air conditioning systems. That innovation meant less power was diverted from driving the car, improving acceleration and gas mileage when the A/C wasn’t in use.

Interestingly, Nash was also the first automaker to develop modern heating and defrosting by circulating hot coolant through a heater core and then directing hot air into the passenger compartment via a fan and ducts. By the late '50s, GM's Frigidaire division, Chrysler's Airtemp group and even Packard had caught up with Nash's modern AC system.

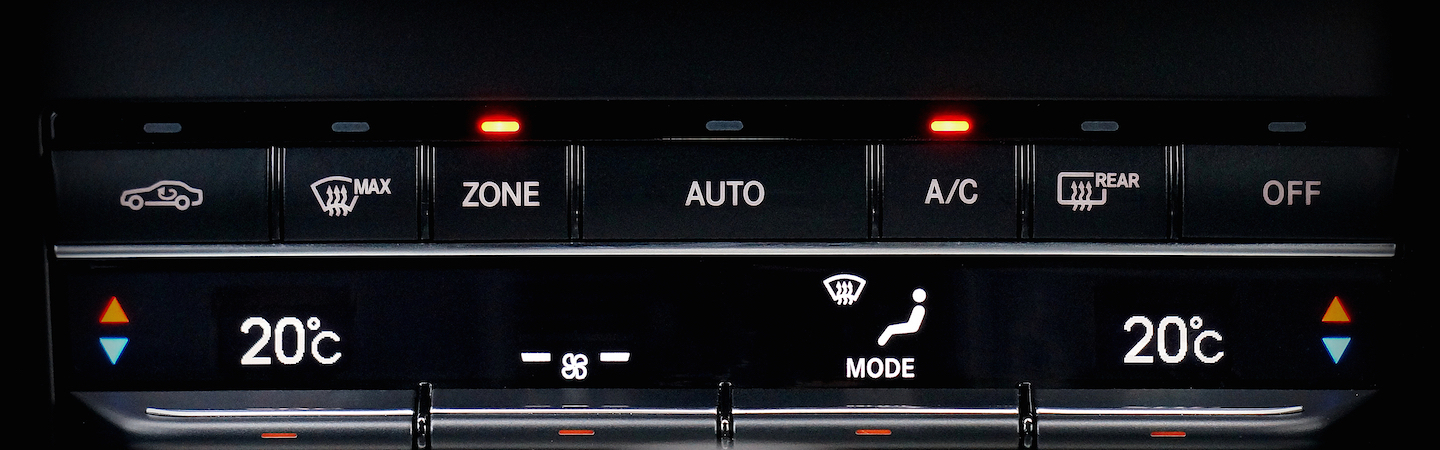

By 1964, Cadillac's "Comfort Control" system mixed cold air from the AC with hot air from the heater core, then regulated the temperature via a thermostat for the first true climate control system. By the late '60s, the AMC Ambassador (!) was the first car to offer AC as standard equipment.

Future forefixers

The air conditioning system is still undergoing upgrades and changes. We've seen the introduction of two-, three-, and even four-zone climate control within a car's cabin, as well as systems for electric cars and hybrids that minimize the function of the air conditioning under certain conditions to improve efficiency. There's even an industry-wide move to switch to something safer and more environmentally friendly. The industry has quite a few options and new ones are being developed all the time.

R1234yf is one of the most popular replacements for R134a; the 2013 Cadillac XTS was the first American vehicle to be equipped with this refrigerant. It's got a notably lower Global Warming Potential number than R134a, and unlike the transition from R12 to R134a there's no modification or retrofit needed to use this new refrigerant. That sounds great, but Daimler found out that R1234yf can leak and ignite in a head-on collision, and that it puts out toxic hydrogen fluoride gas when it burns.

R152a is another alternative; this is nothing more than the propellant in "canned air" that you might use to blast dust off a computer keyboard. R152a is environmentally safe, but has the potential to ignite in a collision.

The advantage of R152a is that it's a lot more efficient than other refrigerants and requires less power from the engine to operate the system. Engineers are experimenting with secondary coils to keep any R152a from the passenger compartment; the refrigerant would cool a water/glycol chiller that would then act as a heat exchanger.

Another alternative is R744, which is essentially just CO2 and is a fraction of the cost of R1234yf. Interestingly, R744 systems don't use a condenser; instead, there's a gas cooler that rejects heat more efficiently than R134a systems. The chief disadvantage of R744 systems is that they operate at pressures as much as ten times that of other systems, which means some challenges in engineering and manufacturing. As of now, R744 systems are more expensive but that's likely to change. It's expected that R744 may be the way of the future; it's nontoxic, nonflammable, environmentally friendly, compatible with heat pump systems and can be designed with smaller compressors and other components.

Like you would expect, innovations continue to roll out in automotive AC systems. Denso has developed an automotive heat pump specifically for electric vehicles, working as a heat exchanger just like a residential heat pump. It's even more impressive when it comes to heating, since EVs can't draw heat from an engine and heating needs drastically cut into battery life and cruising range. eHVAC systems are being developed for hybrids as well, with AC compressors and blowers powered by the battery and regenerative braking, enabling a driver to run the AC for as long as an hour without ever turning on the engine.

In 100 years, there’s no doubt we’ll have many more forefixers to add to this list.

Do you know of any more air conditioning forefixers? Let us know in the comments.