If you’re wondering how to replace copper spark plugs, iridium spark plugs, or other types of spark plugs, check out the following recommended tools. They're what the pros use to remove, gap, and insert new spark plugs properly. And when you're ready, here's how to change spark plugs.

Recommended spark plug tools

Spark plug swivel socket with extension

If a standard 5/8″ or 13/16″ spark plug socket isn’t enough to remove old iridium spark plugs or other kinds of spark plugs, use this special swivel spark plug socket. Its built-in swivel takes up less room so it can fit it into tight spaces. In fact, it takes less room than an ordinary spark plug socket with an add-on wobble extension.

Flexible handle ratchet

You need plenty of angles when you’re trying to remove spark plugs from tight spaces. Combine this flex-head ratchet with the swivel socket and you'll be working like a pro, working faster and smarter.

Spark plug boot puller pliers

Spark plug boots tend to get stuck on the plug over time. Pulling directly on the wire can damage the connection, separating it from the boot. Avoid unwanted damage by using spark plug boot puller pliers to grab the boot and gently work it loose.

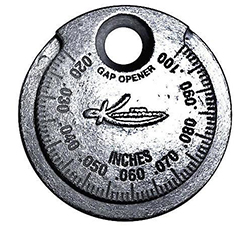

Spark plug gap gauge

Before installing new spark plugs, always gap them according to manufacturer’s specifications. These days, spark plugs do come gapped, but it's a good habit to confirm with a gauge. To use this gauge, find the gap specification and insert the gauge between the plug's center and side electrodes. Then slide the gauge towards the factory specification marked on the gauge. That will bend the side electrode outward, forming the proper gap.

Torque wrench

Spark plugs must be torqued properly during installation or you risk major engine damage. Over-tightening can destroy the threads in the aluminum cylinder head. But if the spark plug is too loose, it can blow right out of the head, taking the threads with it. Instead, invest in a low-range ft-lb. torque wrench and tighten the plug based on the specs provided on the plug manufacturer’s website.

Wire loom spacers

Spark plug wires are spaced in a certain order to prevent arcing-to-ground and cross firing. Wire loom spacers help prevent misfires that can kill gas mileage and possibly destroy the ignition coil, ignition module, or even the powertrain control module.

Anti-seize

Apply just a drop of anti-seize to the spark plug threads (don’t get any on the electrodes or the porcelain). Then reduce the recommended spark plug torque by about 10%. The anti-seize prevents the plugs from permanently bonding to the cylinder head threads.

Spark plug boot grease

Squirt a liberal amount of spark plug boot grease into the boot then install the boot onto the spark plug. This dielectric grease prevents high voltage “flashovers” (voltage leaking out of the boot to ground) and makes future boot removal easier.

Don't have these tools or aren't ready to make the purchase? No worries, you can get free loaner tools at your local Advance Auto Parts.

Get the right parts

Now that you've got the tools, let's make sure you know the right parts. Be sure to use the add your vehicle feature when you shop online with Advance for the correct fit. Depending on how your vehicle is set up, you may need to replace more than just the spark plugs. We cover the common replacement items here.

Spark plug wires

Over time, the spark plug wire’s core conductor and the insulation surrounding it can break down. That leads to arcing and misfires that’ll destroy your gas mileage and possibly damage your ignition module or powertrain control module. Replace the ignition wires with a premium set to maintain proper ignition system operation.

Coil on plug boots

Some coil on plug (COP) style ignition coils have replaceable boots. Extremely high firing voltages can damage the COP boot over time, causing misfires. If the boot on your COP coil is removable, replace it with a new boot and connecting spring to keep the ignition system in perfect running condition.

Distributor cap

After years of distributing high-energy sparks to the spark plug towers, the carbon tip at the base of the center tower can wear down and interrupt the electrical flow from the ignition coil to the individual spark plug towers. Centrifugal force then expels the ground-up carbon around the inside of the cap, causing “carbon tracking.” Carbon tracking causes spark plug misfires. Replacing the distributor cap every time you replace spark plugs is an inexpensive way to keep your ignition system working at maximum efficiency.

Distributor rotor

Replace the distributor cap and rotor as a pair. Doing so ensures the carbon button at the base of the ignition coil tower will mate with the new spring surface on the rotor. Plus, the “distributing” edge on the new rotor will be free of erosion and will transfer the spark with the least amount of electrical resistance.