Starting your car one morning, you're startled to hear it's as loud as a NASCAR racer. There are some other odd symptoms, too, all pointing to a failed exhaust manifold gasket. Here's what you need to know before getting started.

Source | Iain Cameron/Flickr

Why the exhaust manifold gasket matters

The exhaust manifold gasket, as with any gasket, acts as a sealing surface sandwiched between two different metal components. The gasket is made of layers of metal or composite materials, and prevents leaks as the two metal surfaces go through countless heating/cooling expansion and contraction cycles over an engine's operational life. During the exhaust stroke, the exhaust valve opens to allow spent gases to exit the combustion chamber through the exhaust port in the cylinder head. The gasket is an airtight seal against the head, so the gasses pass into the exhaust manifold and on to the rest of the exhaust system. The gasket prevents noxious gases and incredibly high temperatures from escaping the engine at the wrong point.

Signs of exhaust manifold gasket failure

Generally, exhaust manifold gaskets are hardy items, often lasting well over 100,000 miles. A lack of engine maintenance and carbon buildup, however, can cause hot spots in the combustion chambers and exhaust ports. This can cause a gasket to catch fire or expand outward. This is a good reminder to use fuel system cleaners to remove carbon buildup.

A failed gasket also allows fresh air into the exhaust system at a point it wasn't designed for, which could lead to burned exhaust valves. This is an expensive repair and can lead to more damage, so it's best to replace a bad exhaust gasket as soon as possible.

When exhaust manifold gaskets fail like this, the symptoms are rather obvious. Here's what to look for.

- Increased engine noise. Since it isn't passing downstream to the mufflers, the engine noise isn't muffled. This makes a Civic sound like a cammed big block.

- Smells or visible exhaust emissions. A leak lets blasts of untreated exhaust into the engine bay. You can sometimes see this as smoke vapors. It's also incredibly hot and can melt surrounding engine bay plastics.

- Loss of performance. The exhaust and emissions systems are part of a fine-tuned engine on a modern vehicle. With a sudden lack of backpressure and exhaust sensor readings out of norm, the engine's performance suffers.

- Gas mileage hit. Just like the horsepower, the MPGs take a hit, too. When the ECM can't adapt enough to compensate for the failure, the engine uses too much gas.

This is a good project for new DIYers

-

Disconnect the negative battery cable. Ensure the engine is cooled down.

-

Set the parking brake. Use a jack to raise the front of the vehicle and set on jack stands.

-

Use the ratchet and sockets to remove any engine covers or heat shields to gain access to the exhaust manifold bolts. Depending on your engine, this may be easier from below the vehicle.

-

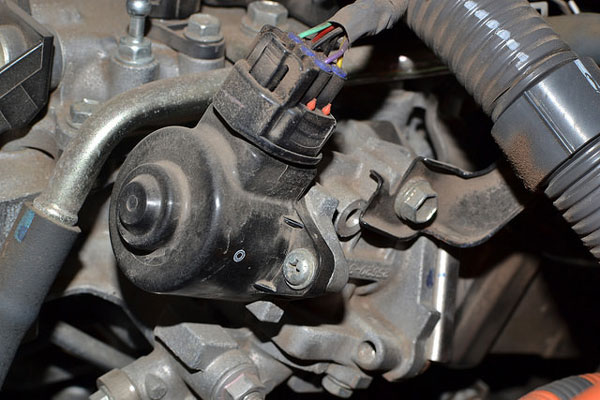

Identify any other components that have to be disconnected at this time, such as the EGR valve intake pipe or dipstick tube. Remove the bolts to the component and set them aside.

-

Spray penetrating oil on the exhaust manifold bolts.

-

Underneath, spray the bolts connecting the exhaust manifold collector to the exhaust pipe flange. Let all bolts soak for 10 minutes.

-

Using a ratchet or a wrench, slowly apply pressure to the exhaust manifold bolts. The bolt should give without an excessive amount of force, which can break off the bolt head.

-

Remove all the bolts, except one at the cylinder head, and then remove all the bolts at the collector. With one hand on the exhaust manifold, remove the final bolt and lift out the manifold.

-

Throw away the old gasket. Spray the exhaust manifold with heavy-duty degreaser or brake cleaner. Once it's dry, examine the manifold for any leftover carbon buildup or cracks. Clean if you find carbon and replace if you find cracks.

-

Spray the cylinder head as well, saturating the area where the new gasket will go. Scrub with shop towels to remove stuck-on deposits.

-

Wearing gloves, place the new gasket on the cylinder head studs.

-

Slide the cleaned manifold back into place. Replace the bolts and hand-tighten until all bolts are in place.

-

Torque each bolt to the proper specs called for in the repair manual, working from the center bolts outward.

-

From here, the rest of assembly is the reverse of removal. After a week of driving, recheck the torque on the bolts to prevent them from slipping out later.

If a bolt doesn't give, spray it again with penetrating oil and give it a few hits from a hammer. The impact vibration will allow the oil to better penetrate rust or corrosion.