Take care of your auto chassis for better safety and longevity

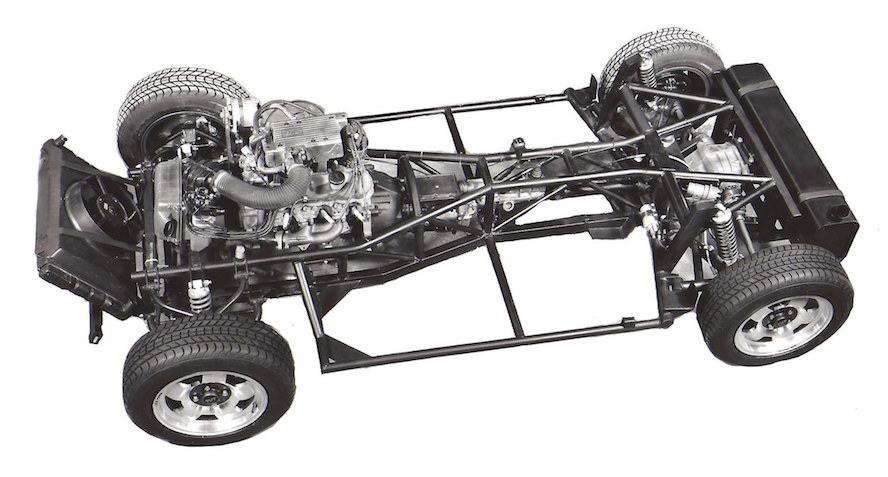

Your auto chassis and driveline components are in constant motion. If your vehicle is front wheel drive, the CV joints drive your wheels. Rear wheel drive vehicles use a driveshaft with U joints for propulsion. Both require lubrication and will fail prematurely if they are allowed to run dry. Most types of vehicles use flexible ball-in-socket joints in the suspension. These joints provide pivot points so your front wheels can turn and your suspension can absorb the bumps. (Learn more about tie-rod ends.)

You should inspect and lubricate your car chassis every six months. Annoying suspension squeaks and creaks are an indication that a bushing is dry and needs attention. Regular inspection and lubrication of your under car chassis and suspension system prevents expensive part failures that could strand you on the highway. Here's what you need to know to do this job yourself.

This is a good project for new DIYers

-

Car chassis components require a variety of lubricants. Don’t mix grease types.

-

Jack up the car safely. Inspect CV joint boots for cracking, tearing, or missing clamps. Replace boots if you find damage. The procedure for changing CV boots can vary—consult a manual before you start.

-

Use a grease gun to lubricate the ball-joints and tie-rod ends. Some manufacturers do not provide grease fittings on OEM tie-rod ends since they are pre-lubricated, sealed units from the factory. A flexible hose helps in tight spots. Apply until grease oozes from the seal. Wipe off extra grease.

-

Inspect the driveline and U joints. Try turning the driveshaft left to right, and see if it has any play when try sliding it fore and aft. Excessive play may indicate worn U joints in need of replacement.

-

U joints also need lubrication. Jack up the rear of the vehicle and secure with jack stands. Place the vehicle’s transmission in neutral.

-

Rotate the driveline to reveal the grease fitting. Lubricate the U joint with a grease gun. Some OEM applications and permanently greased U joints do not have grease fittings.