Diagnosing what automotive technicians call “a no-start condition" was pretty easy before the introduction of computerized engine controls. But one thing to remember when trying to diagnose why your car won't start is that the basics never change. It needs fuel, it needs air, and it needs spark.

These three need to come together at the right time and in the right quantities for the engine to run. That said, it used to be pretty easy to narrow things down to a failed ignition coil, distributor problems, failed fuel pump, obstructed fuel filter, or something else directly tied in to the fuel, air, or spark.

Source | Morven

Let's Get Some Terminology Straight First

One thing that frustrates technicians is the term “turning over." Some car owners think that it means that the engine is running. To a technician, it just means that the starter is successfully engaging the flywheel and rotating the engine's crankshaft. Some technicians will interchange this with the word “cranking."

There are two main types of no-start conditions. Either the starter engages and rotates the crankshaft or it doesn't. We're going to look into some of the major things that can cause your engine to “turn over" (the starter to engage) but the engine not to catch and run.

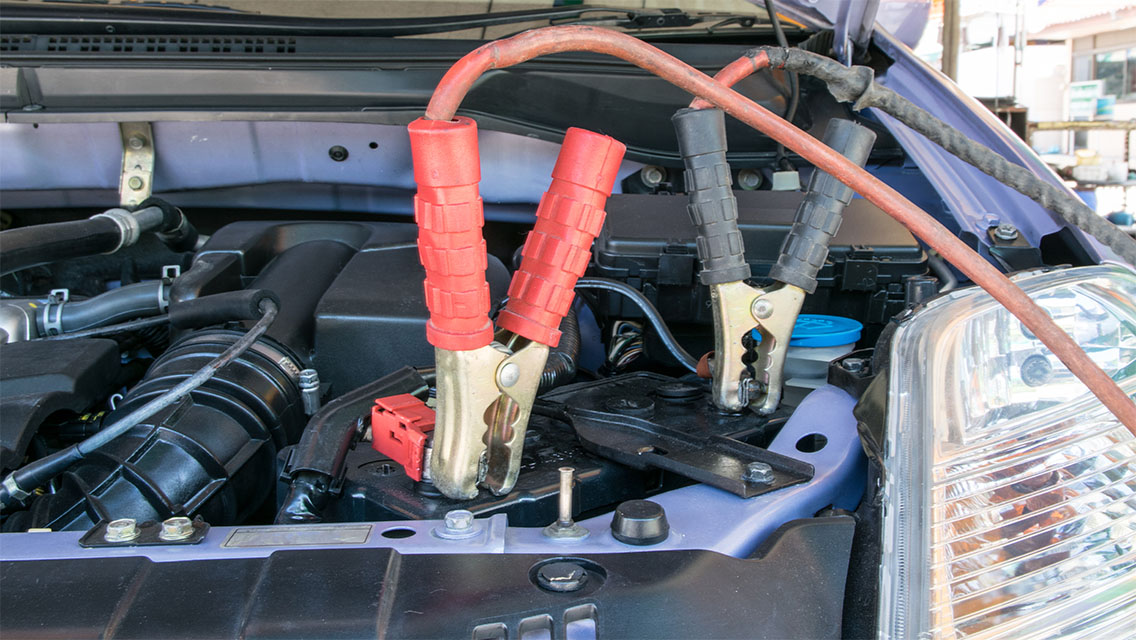

Start with Power

Source | Mike Aguilar

Your battery may have enough juice to turn the engine over, but it might not have the "oomph" needed to start. This is especially true with fuel injected and computer-controlled engines. Those systems are really finicky when it comes to battery voltage.

Check the battery with a multimeter. Make sure it reads at least 12.4 volts. Try and start the car, and make sure it doesn't drop below ten volts when cranking. Do this two or three times to make sure what's known as a surface charge is removed.

If you've confirmed the battery is strong, check the primary and secondary fuse panels for blown fuses in the ignition or fuel system. This is especially important in fuel injected engines and those with electric fuel pumps. You'll need your owner's manual or the repair manual for your particular car from Advance Auto Parts if the load center legend is missing from the cover.

Let's Get Old-School

Source | Wikimedia Commons/Public domain

The first step with carbureted cars is to remove the air cleaner and look down the throat. You should see gas being squirted as you move the throttle. Make sure there's gas and that the pump is working if not. Next, make sure the accelerator/power pump is working and the carburetor float bowls are getting gas. On an older vehicle or one that's been sitting for some time, the carburetor is likely to be gunked up with varnish and deposits from old fuel and may require some coaxing, or even a rebuild. Try an aerosol starting fluid if it's still stubborn. If the choke isn't working, hold your hand over the throat of the carburetor while cranking to close off air.

Some TBI systems won't squirt unless the engine is cranking. They will, however, energize the electric fuel pump for starting when you turn the key. You need to hear a click from the engine bay load center when you turn the key on. You also need to hear the fuel pump power up and prime the system. If not, double-check those relays mentioned above. Use a test light or multimeter to verify that the pump is being energized when you're trying to start the engine. This may require getting into the trunk or under the vehicle.

Check for Spark: Engines with a Distributor

See if the coil is delivering spark by pulling the coil wire from the distributor cap and connecting a spark tester to it before cranking the engine and watching the tester for spark. Without a spark tester, you can disconnect a plug wire at the distributor and hold it a fraction of an inch from its terminal on the distributor and see if a spark will arc to the plug wire.

Replace the coil wire and remove the distributor cap and verify the rotor turns when the engine rotates. If the coil is sparking and the rotor turning, check ignition timing. If there's no spark, check the points or ignition module. If the rotor isn't turning, the distributor shaft has most likely snapped and you need to replace the distributor.

Check the condition of the distributor cap. Is the underside of the cap wet? Wipe out as much of the water as you can and lightly spray it with WD-40 and try starting it again. Look at the contacts closely. See if they are carbon-burnt, pitted, or otherwise worn. Look for carbon-tracking/arcing on the sides of the cap. If any of these are present, replace the cap and rotor and try starting the car.

Check for Spark: Distributorless, Coil-on-Plug Engines

You can't check for spark the way described above on most newer cars because they have what's known generically as a "distributorless ignition system" (one without a distributor) to send the spark to the proper plug at the proper time. Spark timing is controlled by the computer in this case. There will either be a coil pack or two (or more), depending on the number of cylinders.

If your car has either of these, you can check for spark by following these steps:

- Remove a plug wire or coil from the spark plug.

- Connect a spark tester to the plug wire or coil.

- Clip the plug tester to a good ground.

- Have someone crank the engine over as you look for spark. It should be a solid blue or white and you should hear it.

- Repeat for each cylinder.

- For any cylinder/plug wire/coil that does not generate a solid spark, use a multimeter or test light to check for the presence of power to the coil when cranking the engine.

- If no power is detected, use the vehicle-specific repair manual (Available at Advance Auto Parts) to locate the cam/crank sensor(s) and test them for power and for opening and closing as the engine cranks. Adjust or replace as necessary.

Check Ignition Timing

Rotate the engine by either “tapping the starter" or rotating the crankshaft with a socket and ratchet until the groove on the harmonic balancer lines up with the "0" on the timing pointer. Now look at the distributor and verify that the rotor is pointing toward the wire going to cylinder number one. If it's 180 degrees off, rotate the engine 360 degrees and check it again. If it's off just a little, loosen the distributor hold down bolt and rotate the distributor until it does. Put it back together and try again. If you do this, you may want to take a timing light and fine-tune the timing a bit later on.

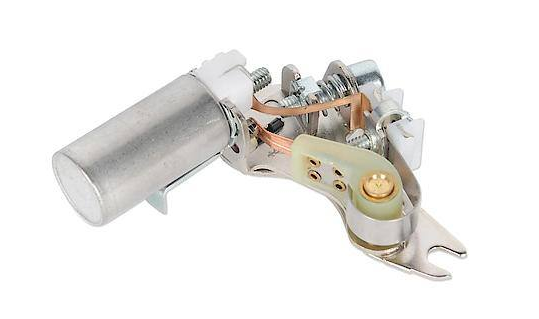

No spark from ignition points

An engine's ignition system can either be points/breaker type or “electronic ignition." In a points/breaker ignition, an arm on a spring rides against a cam and opens and closes the primary circuit to the coil. The field in the coil collapses, causing the spark when the circuit is opened. Turn the crankshaft and see if the arm moves sufficiently for a gap to open in the points. Using a feeler gauge, check and adjust this gap to specification. If the contacts at the end of the arm look pitted or burnt, replace them and the condenser and see if the engine starts.

No spark from coil-electronic ignition

Source | Top Left: Advance Auto Parts Top Right: Advance Auto Parts. Bottom Left: Advance Auto Parts. Bottom Right: Mike Aguilar

Electronic ignition replaces the points with a module that is triggered by a ring rotating on the distributor shaft. The ignition module on some older cars could be found in the distributor under the rotating assembly. Chrysler put their module on the bulkhead. The driver-side fender skirt was the normal home of the Ford “Red" and “Blue" ignition modules. Advance offers free testing of most ignition modules

What else could be wrong?

Source | Mike Aguilar

If the engine still won't start, the most likely culprit is a lack of compression. Advance carries compression testers that thread into the spark-plug holes and read compression when you turn the engine over. After making sure the engine won't start when you crank it, remove one plug and thread the tester in the hole. Crank the engine for two to three seconds and read the gauge. Replace the plug and wire and repeat the process on all cylinders. Serious problems are present if there is a large variance between cylinders or one or more cylinders have no compression.

Check computers for codes

Source | Mike Aguilar

Computerized engines need numerous signals to run properly. These signals can be corrupted, erroneous, or nonexistent or they can be misinterpreted by the computer causing the no start. Problems in these circuits and systems usually cause the Check Engine Light on the dash to illuminate but not all of them do. You have to ask the computer if any error codes are present. Advance Auto Parts has a variety of testers for newer cars for “pulling codes."

Pulling codes means you're using a scan tool to ask the computer if it's found and stored problems (known as codes) with the engine. The image above (on the left) shows the computer port where the scan tool is connected. Turn the key to the "On" position after turning on the tool. Navigate through the menus (Check the manual on how to do this) and select the option (something like) "Pull Codes" or "Query for Codes."