Power steering (p/s) is what allows you to easily rotate your steering wheel when your car is either stationary or moving slowly. Some newer vehicles now have electric power assist, which means less parasitic drag on the engine, but most vehicles on the road still use hydraulic power assist.

Leaks in power-steering hoses can diminish the effectiveness of the system and are also messy. Power-steering pumps that leak, make noise, or don't supply enough pressure for the steering system will also diminish the system's effectiveness.

This is a challenging and technical project

This is a project that needs some know-how

- Cut the lo-side/return hose close to the reservoir.

- Slide a clamp on each side of the cut.

- Slide the filter into both ends of the cut hose. It will be a tight fit.

- Grip the clamps with pliers and slide them over the hose ends to clamp the filter in place.

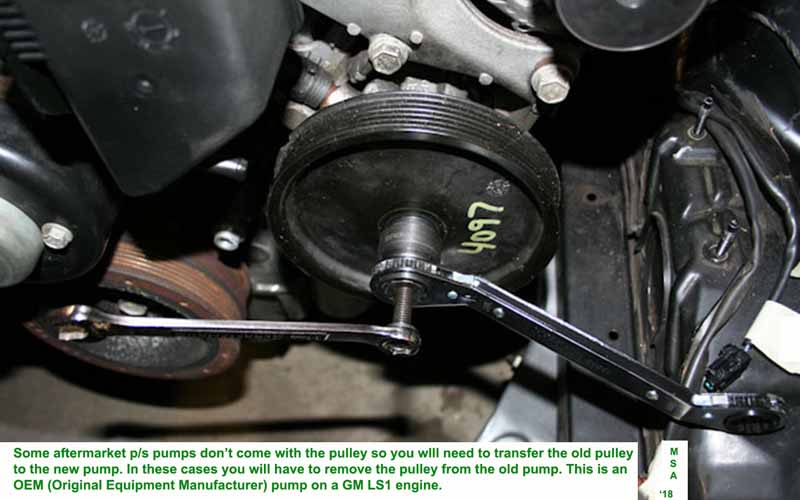

- Some pumps don't come with a pulley. You will have to transfer the pulley from the old pump in these instances. Advance Auto Parts has a power steering pump pulley puller that will help with this. Slide it over the pulley, lock the jaws in place, and turn the bolt to remove the pulley. Some vehicles, particularly ones with a plastic pulley may require this puller tool instead.

- “Burping" the system is required after completely draining the system and consists of filling the reservoir completely, starting the engine, and slowly turning the steering wheel left and right as far as it will go until there is no more air in the system/no more bubbles appear in the reservoir as you rotate the steering wheel. On most vehicles, this is done at the p/s reservoir while on others there is a bleed port built into the system. See your vehicle's repair manual to see what you have.

- Be sure to check all hose connections with the engine running to make sure there are no leaks.

The jack and jack stand are not required to replace a p/s pump on a RWD vehicle, but they are required to replace hoses on most vehicles and pumps on just about every FWD vehicle on the market.

Power Steering Hose Leaks and Failures Are Easy to Spot

Source | Mike Aguilar

If the leak in a power steering hose is big or has been leaking for some time, it's going to be pretty easy to spot. The hi-pressure hose, called the hi-side hose, will usually start leaking where the metal ends are crimped to the high pressure rubber hose. Lo-side hoses—identified by being clamped to a tube on the back of the power steering pump—will either leak at the junction of this tube and the hose or at the rack/steering gear.

Source | Mike Aguilar

Although rare, these hoses can also develop pinhole leaks in the hoses themselves. Age, temperature extremes, and wear can also cause failure in the rubber of these hoses as well. A failed power steering hose isn't always going to leak though. One of the signs of age and temperature extremes is dry rot and cracking in the hoses. Even if it's not leaking currently, a cracked hose should be replaced.

Power Steering Problems Aren't Always Visible or Obvious

Caption: Don't jump to conclusions and assume this leak is in the hi-side hose. It could actually be in the fitting on the back of the pump. Source | Mike Aguilar

Some signs of failure in a power steering pump are obvious: leaks, a missing or melted belt with burn marks on the pulley, cracks in the body, and broken fittings are a few. Loss of steering power is probably the most obvious sign that a power steering pump has failed.

In the case of a leak, wind can blow fluid around all over the place and make it difficult to pinpoint exactly where the leak originates. If things are really greasy and messy under there, blast the area with some brake cleaner and let it dry. Next, spray athlete's foot powder or baking spray with flour all over the whole area - any leaks will make a trail through the residual powder and will be much easier to pin down.

Image by author

If your power steering pump is “groaning" you may either have a bad pump or the fluid level is low and air bubbles have been introduced into the system. If the reservoir is low, refill it and start the engine. Slowly turn the steering wheel through its full arc a number of times and recheck the fluid level. If this doesn't stop the groaning from the pump it has failed and will need replacement.

Test Your Power Steering Pump by Hand

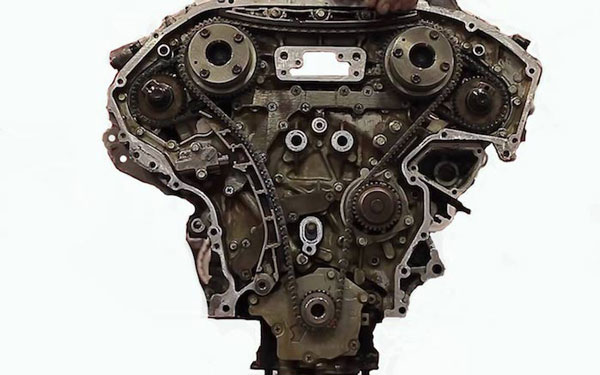

A loss of power steering can be attributed to either a bad pump or a bad rack and pinion or steering gearbox. You can perform a basic test of the pump by removing the hi-side hose from the rack/gearbox and spinning the pump by hand with the end of the hi-side hose at or above pump level. If the pump is working turning the pulley will pump some fluid out of the hose. If not, the pump is not producing pressure and needs to be replaced.

Special Wrenches Should Always Be Used on Power Steering Hose Fittings

Image by author

Sure, a regular 9/16 inch open end wrench can will work to remove that fitting from the pump or gear but it can also round that fitting if it's really tight. By the same token locking pliers should also never be used on these fittings. Flare nut wrenches, also known as line wrenches, are designed to prevent this by making contact with more sides of the fitting and are perfect for a nut made of soft metal like aluminum or brass. Line wrenches are also advisable for soft metal nuts on things like AC lines, brake lines and transmission cooler lines, for the same reason.

Procedures Change but the Basics Don't

Image by author

The basics of changing a power steering pump are drain the system, remove the hoses from the pump, remove the belt, and remove the pump after removing the bracket bolts. Exactly what you have to do to accomplish this will differ between manufacturers and even between models and sometimes model years. A p/s pump may be mounted high on the engine or it may be at the lower right or left. The differences lie in where there the hoses attach and where the bolts for the brackets are. You might be able to get both front bracket bolts with a wrench from the top or you might need to use a socket through a hole in the pulley for one or both. Likewise, the rear bracket bolt may be high or low on the pump.

Source | Mike Aguilar

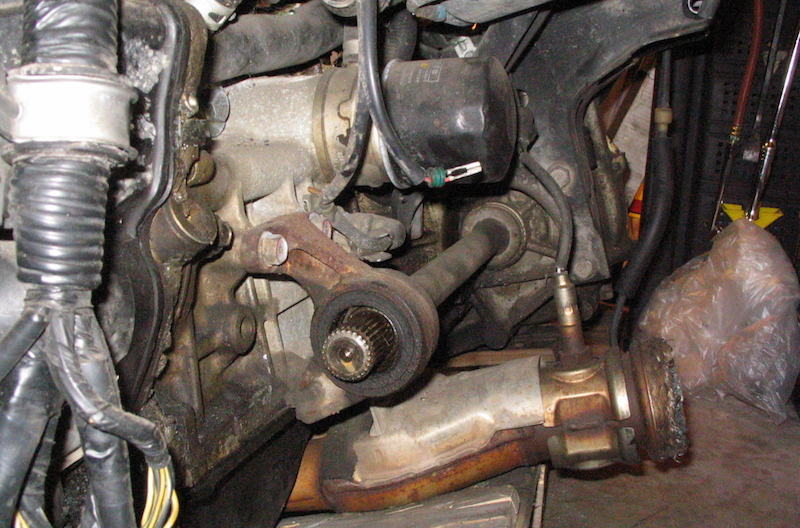

That's not even getting into the differences between FWD and RWD vehicles. Getting at the pump and/or hoses on almost every FWD car will require you to jack up and support the front passenger side of the car and remove the right front wheel. It is highly recommended that you pick up a manual for your specific vehicle. This will not only describe the exact steps you need to follow to replace either a pump or a hose but it will also mention anything you need to be aware of that is particular to your vehicle. You might also want to check your collection of socket wrench extensions, flexi-heads, stubby wrenches, adapters and other tools for getting into tight areas, because you might need them.

Replacing the High-Side Power Steering Hose

Source | Mike Aguilar

As mentioned before, open end wrenches should not be used to remove the fittings on p/s hoses, flare nut wrenches should. There will be times, however, when a large open end wrench will be needed to hold the base fitting (in either the pump or the gear) while loosening the fitting. Replacing the hose can be broken down into seven basic steps:

1.Remove the hose(s) from the gear (rack or worm gear/gearbox) and drain into the drain pan

2. Replace the hose and refill the reservoir. Start the engine and turn the wheel from side-to-side a few times to circulate the fluid. Remove the hose again and drain the system.

3.Remove the hose(s) from the pump

4.Remove any supports or brackets on the hose(s)

5.Reinstall the hose(s) to the gear

6.Reinstall the hose(s) to the pump

7.Reinstall any supports or brackets for the hose(s)

8.Refill and burp the system. "Burping the system" means removing air bubbles. To do this, start the engine and slowly turn the wheel from one end to the other a few times with the reservoir cap off. Top off as needed.

Replacing a Low-Side Hose

Source | Mike Aguilar

Regular hose clamps are enough to keep lo-side hoses sealed because they're under less pressure. To remove a lo-side hose from the pump you will need either a flat screwdriver or a nut driver/socket (1/4 or 5/16 inch) to loosen the clamp(s). The lo-side hose will be attached to the gear/rack in some cars with a threaded fitting like the hi-side hose while on others the hose will simply be clamped to a stub from the rack/gear. Again, removal can be broken down into seven basic steps:

1. Remove the hose from the rack/gear and let the system drain into the drain pan

2. Flush out the system. You can do this by adding clean fluid and running the engine for a few minutes.Take the hose back off.

3. Remove the clamp from the hose at the pump and remove the hose from the pump

4. Remove any bracket or support

5. Reinstall the hose at the gear/rack

6. Reinstall the hose at the pump

7. Reinstall any support/bracket

8. Refill and burp the system

Install a Power Steering Filter to Prevent Early Failure

A power steering filter will help ensure long life for the new power steering system components. If your power steering system isn't already equipped with a filter you should install one like the Cardone universal filter linked above after thoroughly flushing the system. Installation is four steps.

Replacing a Power Steering Pump

Image by author

Image by author

Replacing the power steering pump is another project that can be broken down into seven basic steps:

1. Remove the lo-side hose from the gear and let the system drain

2. Replace the hose and refill the reservoir. Run the engine while turning the wheel. Remove the hose and all the system to drain again.

3. Remove the lo-side hose from the pump

4. Remove the hi-side hose from the pump

5. Remove the bolts from the bracket and remove the pump from the car

6. Reinstall the pump and bracket bolts

7. Reinstall the hoses and refill and “burp" the system

8.Refill and burp the system