Your car won't start, but the battery checks out. Is it a fuel issue? Is the fuel pump working? Is enough fuel pressure getting to the injectors? Here's how to find the answers to your questions with a fuel pressure tester, and how to use it to diagnose your starting/running issues.

Source | Advance Auto Parts

How You Can Test Fuel Pressure

As you probably know, an engine only needs four things to run: air, fuel, spark, and compression. Checking an ignition tester can easily verify ignition operation, and a fuel pressure tester is nearly as easy to operate. The simple design consists of a gauge attached to a fuel hose and multiple fittings. The various fittings connect to the fuel system of nearly any vehicle. When it's connected and the fuel system is pressurized, the tester displays the pressure in psi on a large gauge visible from inside the vehicle. This allows you to verify fuel pressure while sitting in the driver's seat, making testing fuel pressure a one-person operation.

So you might be wondering what “good fuel pressure" looks like. The answer is: It depends on the engine. Some older throttle-body injected systems need as little as 10 psi, while multi-port injection can see as high as 60. Even the same vehicle can vary, as the LT1 V8 in the 1996 Corvette wants 40-42 psi, while the next year LS1 V8 should see 58 psi. If you don't know what your engine needs, grab a repair manual and check the specifications section.

While zero fuel pressure means the engine won't run, low pressure sometimes allows engine operation with issues. A slow start-up, low performance, misfires, and stalling are common signs of low fuel pressure. High fuel pressure will cause excessive fuel consumption, black smoke from unburned gas, an overheating catalytic convertor, and rough idle.

Before You Buy a Tester

If you don't have a fuel pressure tester, let's try a few things before you go out and rent or buy one. Step one in fuel system problems sounds goofy, but you need to check that there is actually gas in the tank. Don't trust the fuel gauge even if it shows a full tank, as the gauge could be faulty. Add at least two gallons to the tank and try another start. If it fires up, check the fuel gauge for internal failure and replace if needed. If the new gauge shows the same high fuel level, the issue is a failed fuel sending unit in the gas tank. The float arm is stuck, or the resistor has failed. Either way, replace the sending unit.

The next step is to verify that the fuel pump works. Head back near the fuel tank and have an assistant turn the ignition switch to "On." Listen for a two-second whir, hum, or series of rapid clicks as the fuel pump pressurizes the fuel line to the engine. No noise? That means the pump is not getting power or it has failed. Check the fuel pump fuse and relay. If both are good, check the wiring to the pump. If voltage is present when turned to "on," then the pump has failed. Here's how to swap it out. If there's no voltage at the pump, check the condition of the wiring and for solid connections. Once the pump has power and is delivering fuel, it's time to break out the fuel pressure tester.

How to Connect a Fuel Pressure Tester

Note: Fuel vapors are even more flammable than liquid fuel, so be sure to perform these steps in a well ventilated area with a fire extinguisher nearby.

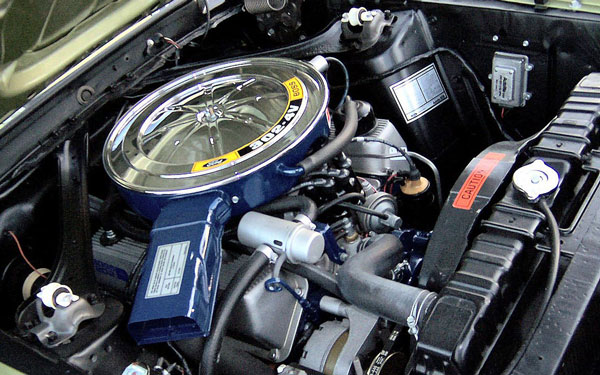

- With an entirely cold engine, pop the hood. Find a Schrader valve fitting on the fuel rail. Most vehicles will have them, although it may be hidden under a fuel rail cover or other plastic engine cover.

- Remove the Schrader valve cap. Attach the appropriate fuel pressure tester fitting. Make sure it threads on properly for a leakproof fit. Turn the ignition to "on," not start. Check the psi reading. Wait and watch for a psi drop indicating a leak in the system. If it's still reading the same after 5 or 10 minutes, the system is holding pressure well.

- If the fuel pressure drops over 10 minutes—let's say it loses 20 psi in that time—that means there is a leak in the fuel system. Look for drips underneath to help narrow down the location. Realize it could be leaking internally from a bad fuel injector.

- Then start your engine, and let it idle. You should see steady fuel pressure, within a few psi of recommended pressure. Once warmed up, give the engine a slow rev, making sure pressure rises with RPMs. If your fuel pressure holds steady, rises with engine speed, and is at recommended pressure, then your engine problem does not seem fuel related.

Understanding Fuel Pressure Readings

So now that you have a measurement of fuel pressure and what a repair manual recommends for your vehicle, let's look at what could cause your fuel issue.

- Zero fuel pressure – This means the pump is dead or not getting power. First, check the fuel pump fuse. Then verify power to the pump with a multimeter, and if it's good, swap out the fuel pump.

- Low fuel pressure – The fuel filter could be clogged, or the pump could be failing. If it is a serviceable type filter, spend just a few bucks and change the fuel filter. This could also be improper tank venting, an emissions issue cause by a loose gas cap. Check that the cap gasket isn't damaged, and tighten it until it clicks.

- High fuel pressure – This one has a couple of suspects, but start by looking for a clogged or kinked fuel return line. This could also be a bad fuel pump driver module or powertrain control module. These would likely store a code and show a "check engine" light. High fuel pressure can also be caused by a faulty fuel pressure regulator.

Have you ever solved a fuel pressure problem? Let others know what to look out for in the comments below.